Layers depend on customer needs.

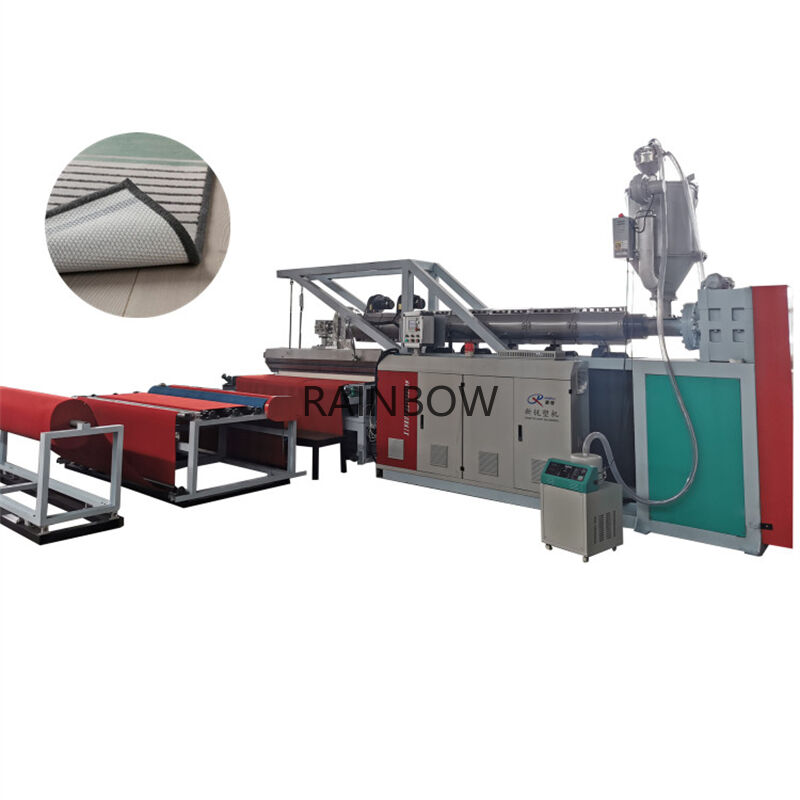

2-Layer & 5-Layer Cosmetic Tube Extrusion Lines

Product Overview

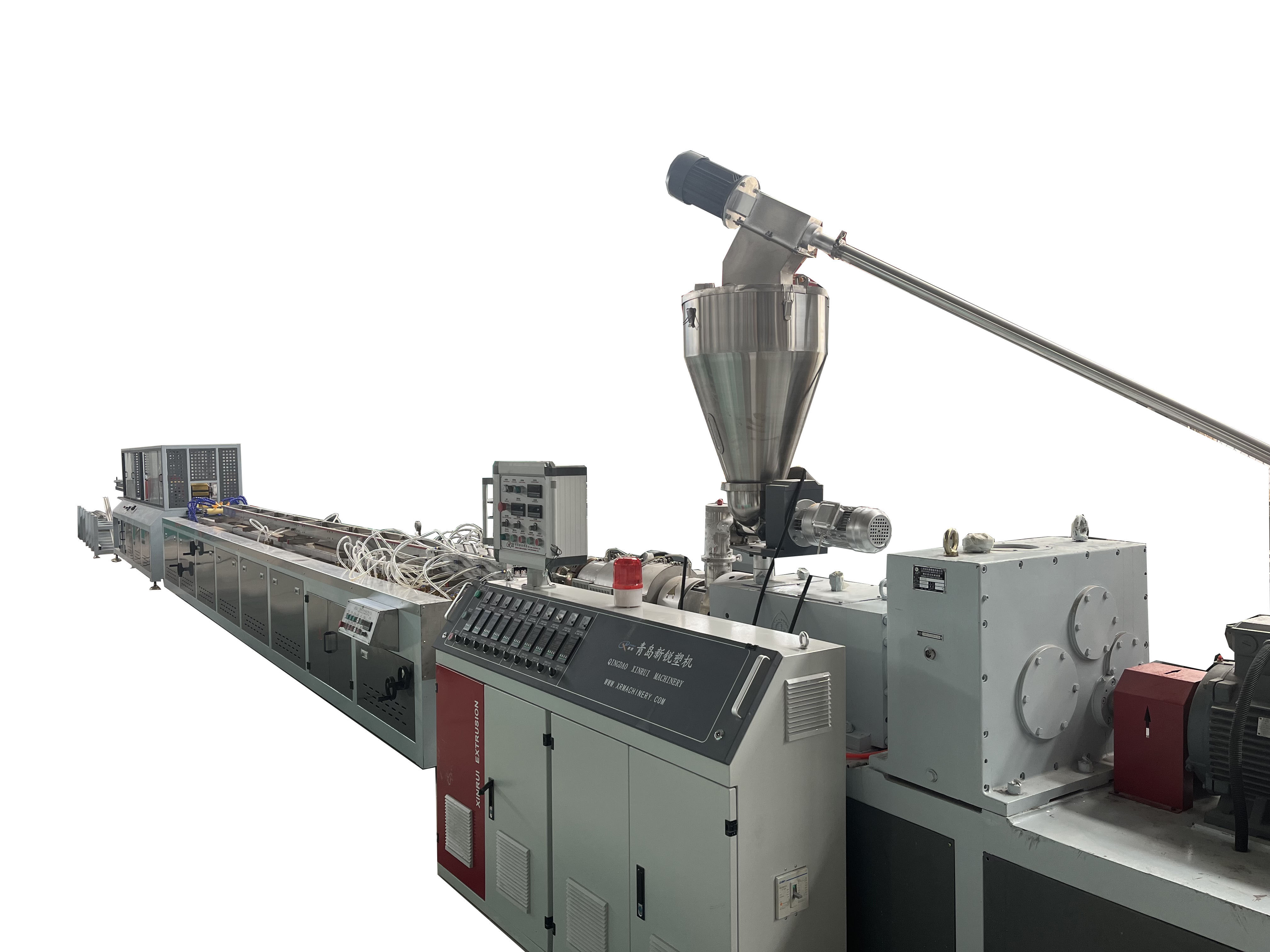

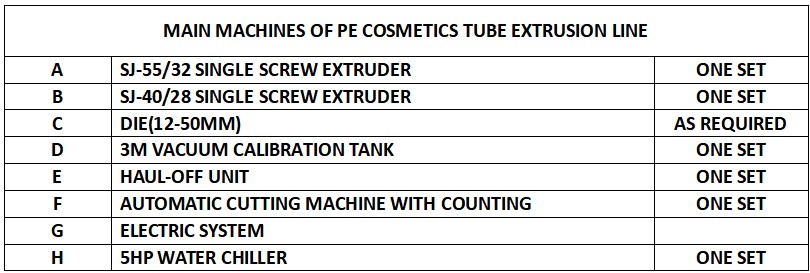

This production line is equipped with an advanced PLC programmable controller and a full-color touch screen, enabling intuitive human-machine interaction. The core components include a co-extrusion die for two-layer PE cosmetic tubes, a vacuum pump and cooling tank, a high-speed synchronous tracking and cutting machine, and an electrical control cabinet. The line supports a variety of materials such as LDPE, LLDPE, MDPE, HDPE, etc., and can also provide custom materials according to customer requirements to meet the packaging needs of different products.

Product Advantages

Stable and Efficient Drive System

Equipped with a reliable motor and gear reducer, the line ensures synchronized operation and supports extrusion speeds up to 15 m/min — ideal for high-efficiency, large-scale production.

Precise Temperature Control

Independent temperature control for screws and dies ensures optimal plasticizing, improving product quality and reducing defects.

Efficient Cooling and Forming

A dedicated vacuum and cooling system ensures uniform tube wall thickness and faster forming, while allowing quick spec changes for greater flexibility.

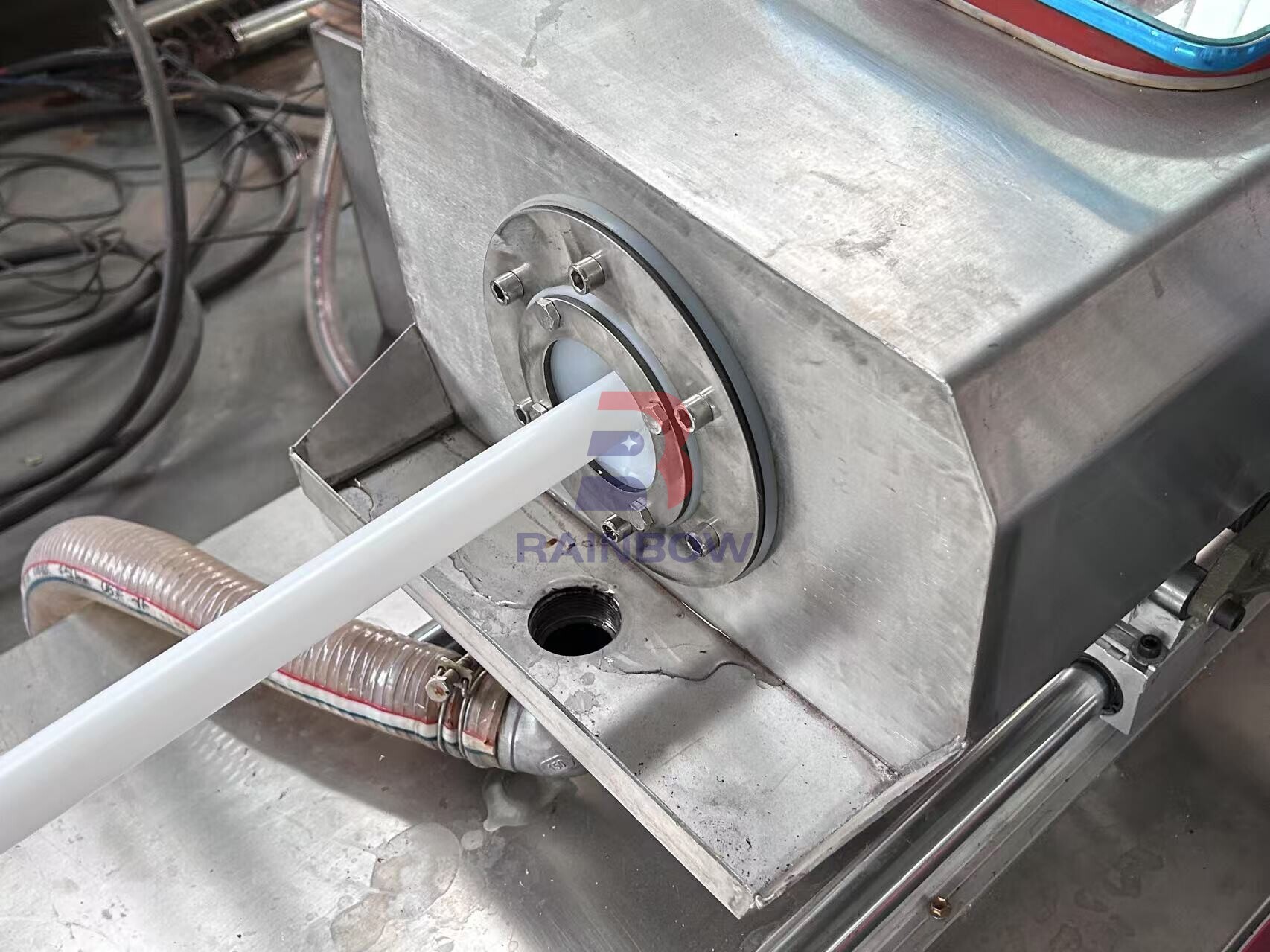

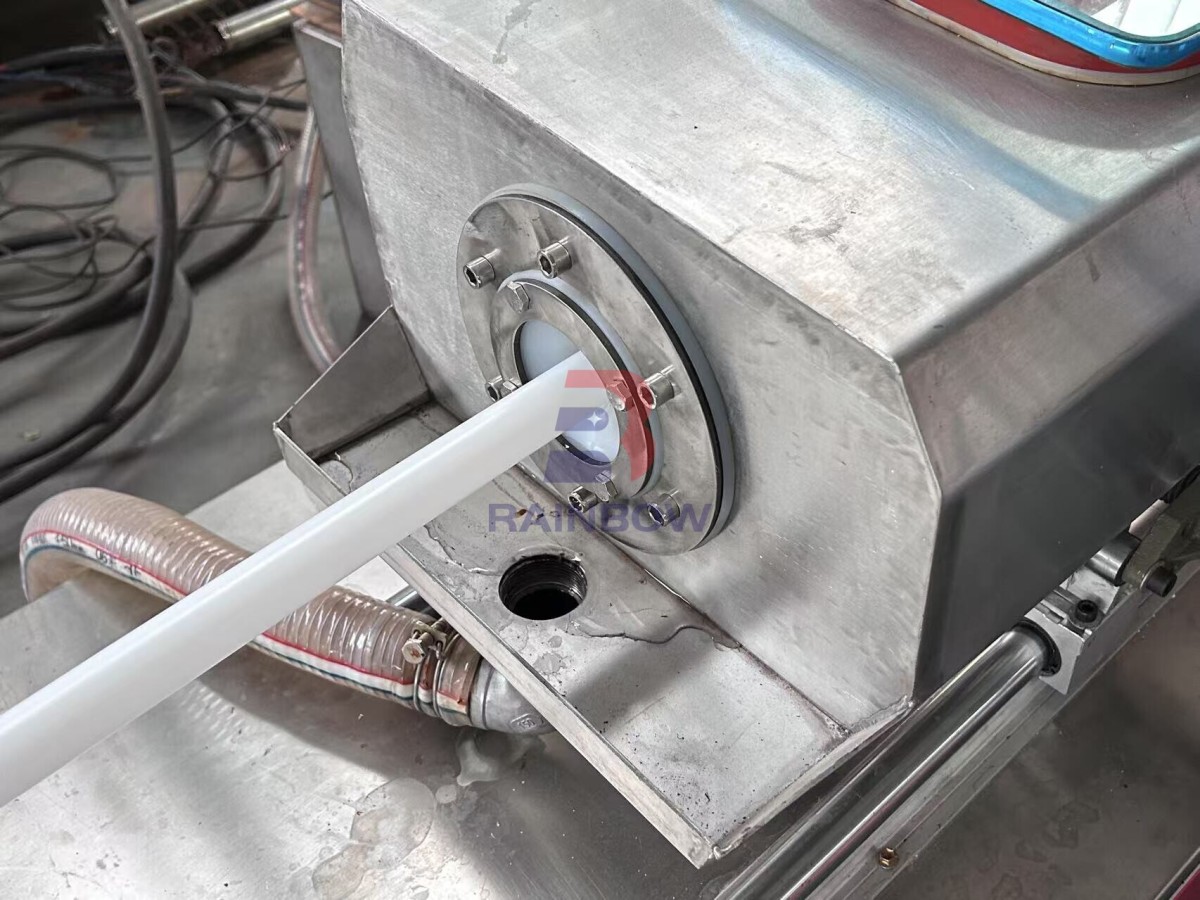

Innovative Die Design

Specially designed dies ensure smooth extrusion and uniform material distribution, reducing changeover time and material waste.

Precision Cutting

The PLC-controlled tracking cutter delivers clean, burr-free cuts with high accuracy, ensuring consistent product quality.

User-friendly Interface

A modern control panel with clear layout enables easy operation, featuring functions like length and speed adjustment, and real-time monitoring.

Reliable Components

Using trusted brand-name parts, the line ensures stable performance, fewer breakdowns, and lower maintenance costs.

Request A Quote