What Is The Key To Manufacturing Precision Medical Tubes?

Modern healthcare demands tubing that delivers both flawless performance and uncompromised safety. To achieve this, manufacturers must rely on extrusion systems that integrate mechanical precision, material compatibility, and intelligent automation. At the heart of this process lies the extrusion machine—the engine that transforms raw polymers into high-quality medical tubing.

Why Are Medical Tubes Crucial in Modern Healthcare?

Medical tubing is a critical component in today’s healthcare systems, widely used inIV infusion, blood transfusion, catheterization, respiratory care, anesthesia, and more. Due to their direct interaction with the human body, stringent requirements are placed on safety, accuracy, and material consistency. As medical technology evolves, the demand for enhanced tube functionality, transparency, and adaptability increases—driving innovation in manufacturing processes.

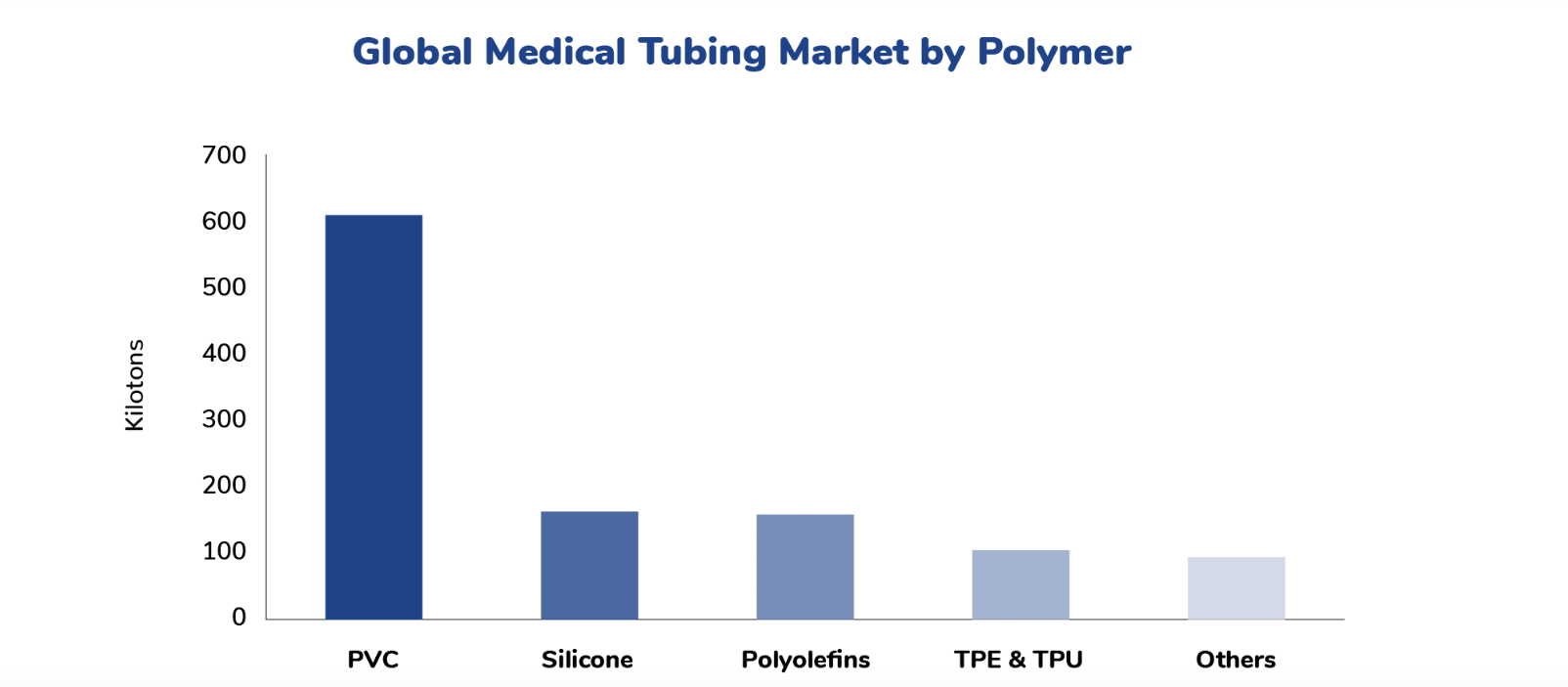

Why Does PVC Remain the Leading Material for Medical Tubes?

Polyvinyl chloride (PVC) continues to dominate the single-use medical tubing market thanks to its outstanding properties:

Excellent biocompatibility: Safe for body contact, with minimal risk of allergic or rejection reactions.

High transparency: Enables medical staff to clearly monitor fluid flow inside the tube.

Great processability: Thermoplastic properties allow for easy shaping into various specifications.

Cost efficiency: Lower production costs make it ideal for large-scale manufacturing.

Strong flexibility and customizability: PVC can be adjusted in hardness, color, and transparency, adapting to diverse medical applications.

Which Medical-Grade Polymers Are Emerging in the Market?

To meet more complex clinical requirements, several high-performance medical-grade polymers are gaining traction:

PB (Polybutene): Offers excellent heat resistance and oxidation stability, suitable for short-term internal devices.

TPU (Thermoplastic Polyurethane): Known for superior mechanical properties, abrasion resistance, and biocompatibility—ideal for long-term implants.

PP/PE (Polypropylene/Polyethylene): Chemically resistant and cold-resistant, suitable for urinary and respiratory catheters.

TPE (Thermoplastic Elastomer): Highly flexible and elastic, ideal for bendable or stretchable tubing.

PA (Polyamide/Nylon): High strength and durability, used in high-performance or long-term medical tubing.

Rainbow’s extrusion line supports a wide range of materials, enabling efficient production of various types of medical-grade tubing and expanding potential applications.

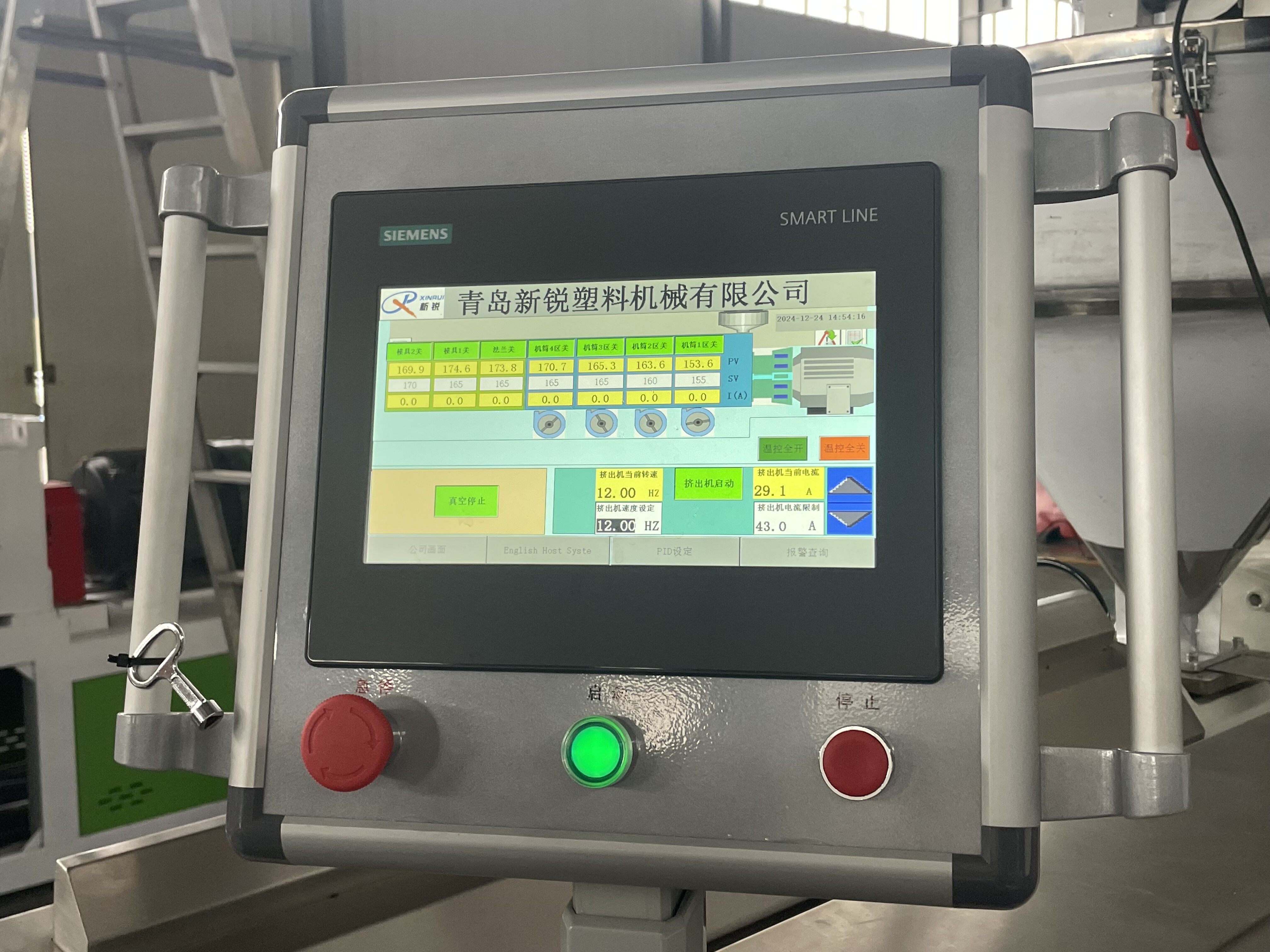

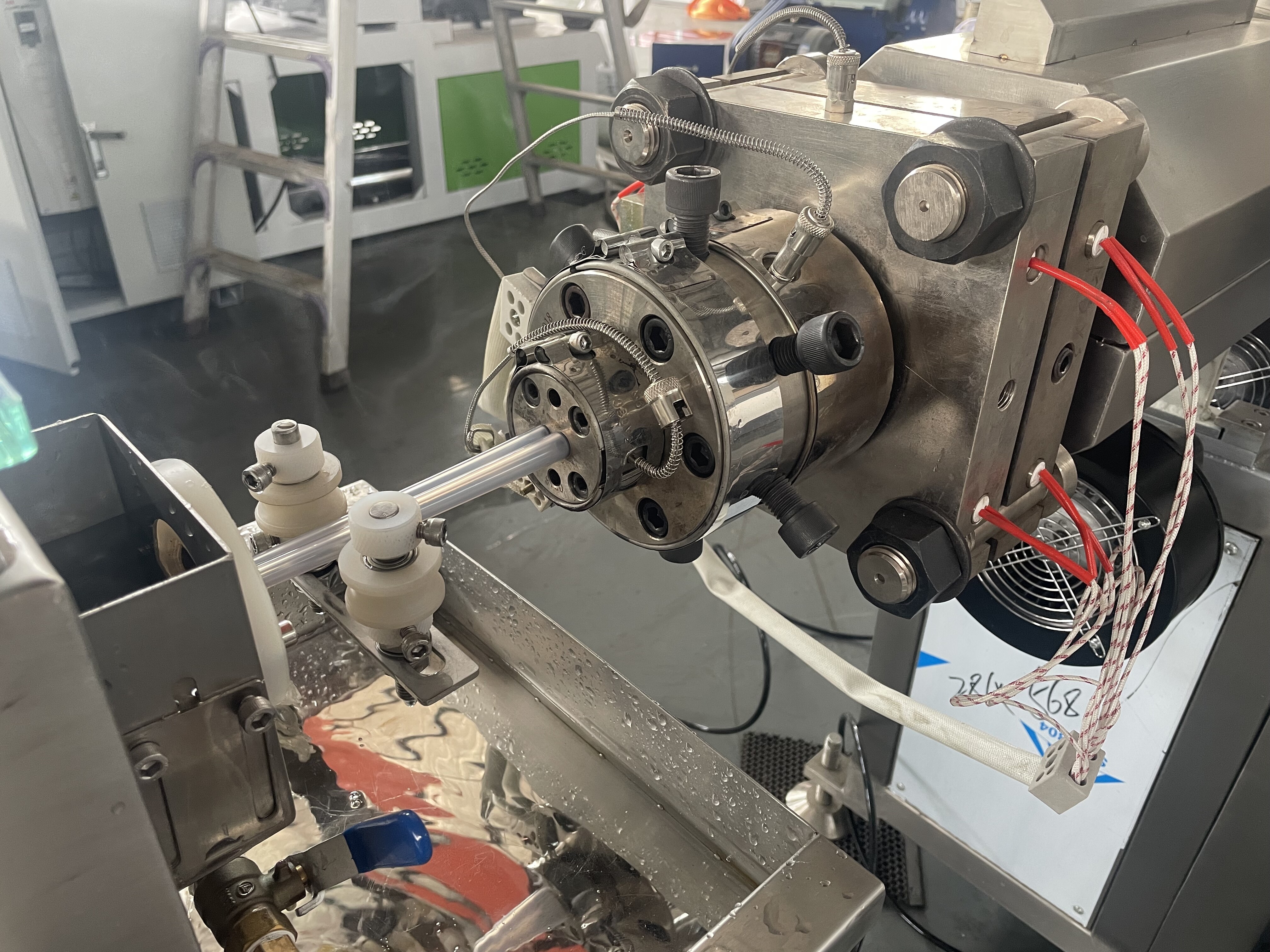

How Has Rainbow Validated the Line’s Performance?

Rainbow has successfully completed trial runs of its medical tube extrusion line, showcasing a major breakthrough in the production of single- and multi-lumen PVC hoses. The line demonstrated high production efficiency, product consistency, and quality—fulfilling stringent medical-grade requirements and supporting applications ranging from infusion to complex catheters.

Which Extrusion Technologies Are Most Commonly Used?

Single-layer extrusion: Suitable for general-purpose applications such as IV tubes and urinary catheters.

Multi-layer co-extrusion: Used to produce composite structured tubes with special functions, such as antibacterial layers or soft-hard composite layers.

Is Medical-Grade PVC Sustainable?

Yes! PVC is a recyclable material.PVC pipes, for example, can last over 100 years and be recycled up to 10 times without the need for virgin materials. Medical-grade PVC recycling is already well-established, beginning over a decade ago in an Australian hospital and now active in nine countries worldwide. Rainbow’s equipment is designed with these sustainability goals in mind—contributing to a greener future for healthcare manufacturing.

With advanced extrusion technology and precise engineering, Rainbow delivers high-performance, reliable, and sustainable solutions for medical tubing—driving the global medical device industry toward higher standards and greater efficiency.

Request A Quote