Production capacity: 0-80 meters/minute

Precision Catheter Medical Tube Extrusion Line PVC Material

Equipment Introduction:

1. Applicable Material:Medical-grade PVC

2. Equipment Purpose:Extrusion production of precision medical PVC tubes

3. Production Capacity:0-80 meters per minute

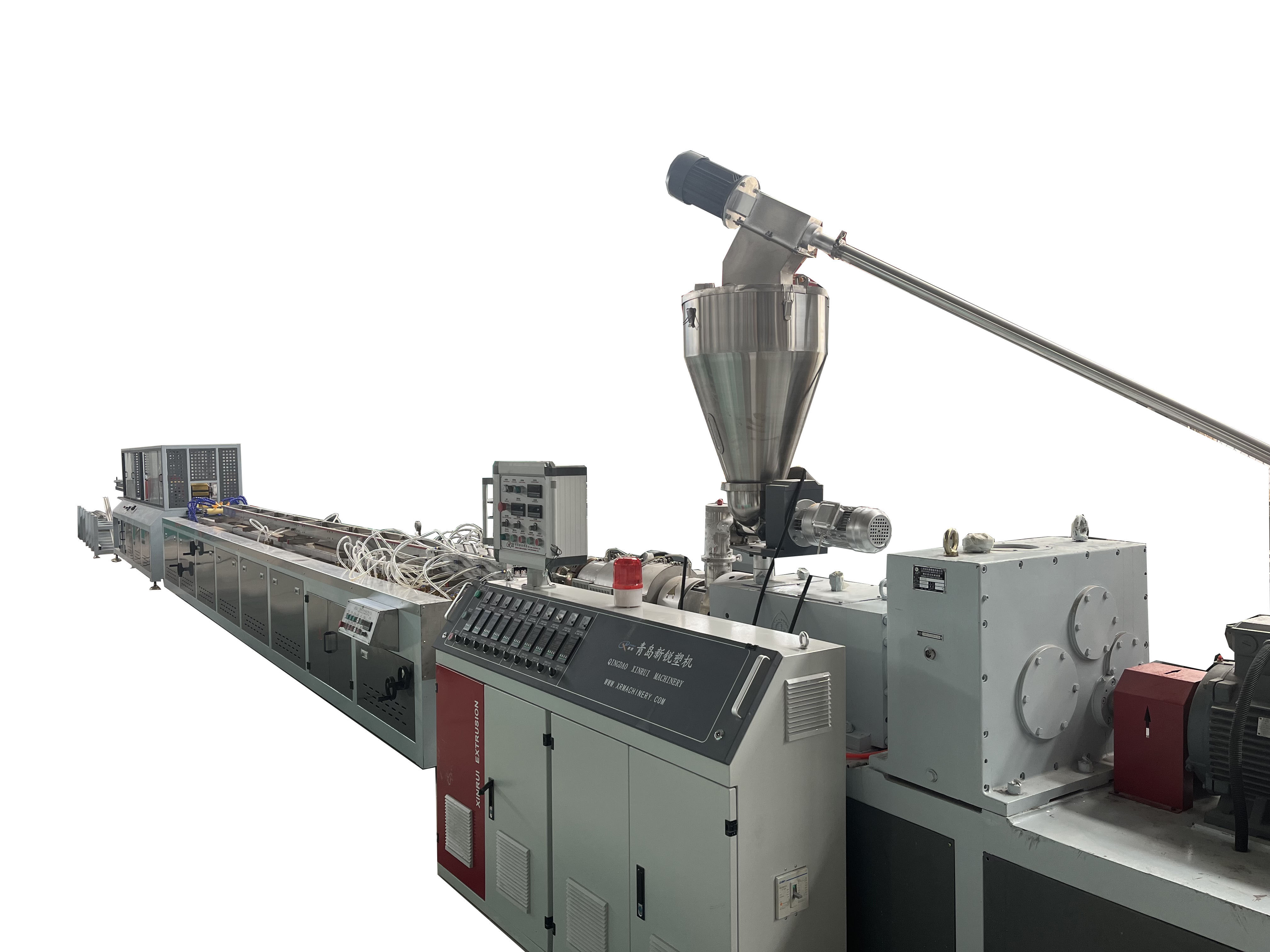

4. Equipment Composition:YJ65 main unit — mold — medical-grade cooling water tank — medical-grade precision traction cutting machine — conveying collection tank

Equipment Overview and Technical Advantages:

1. The entire production line is designed to meet the dust-free and sterile conditions required for medical use. The cooling water tank is fully sealed with tempered glass, and the traction cutting machine is equipped with a transparent acrylic cover.

2. The specialized screw for PVC soft materials has strong plasticizing capability, ensuring a surface free of crystal points.

3. The entire machine is made of stainless steel. The main unit is controlled via a full touchscreen, and the traction cutting machine is also operated through a full touchscreen, offering high cutting precision and user-friendly operation.

1.Medical-grade YJ65 Single Screw Extruder

This equipment is specifically designed for the extrusion of medical-grade materials, ensuring high precision and compliance with medical standards.Equipped with Siemens control system.

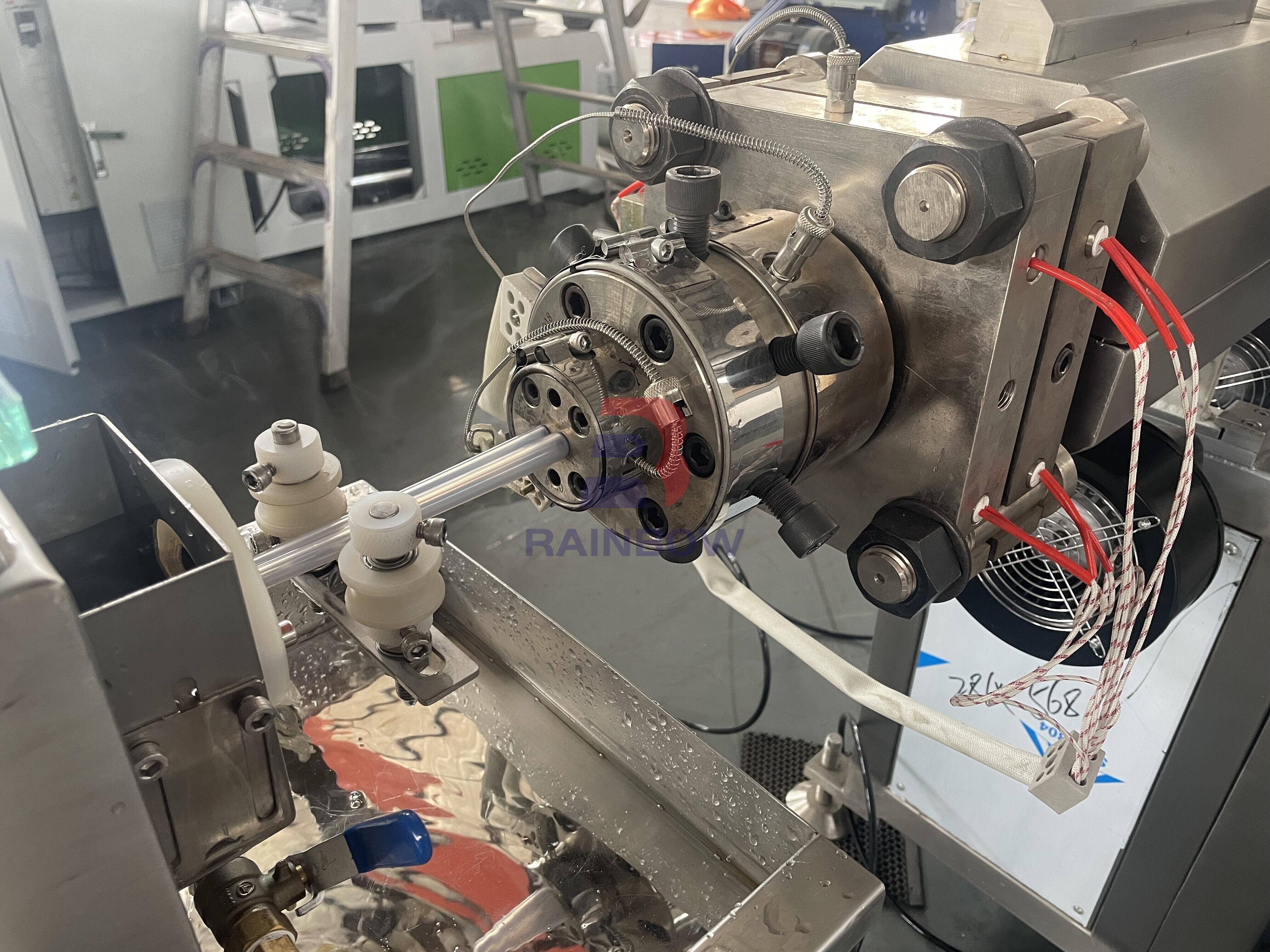

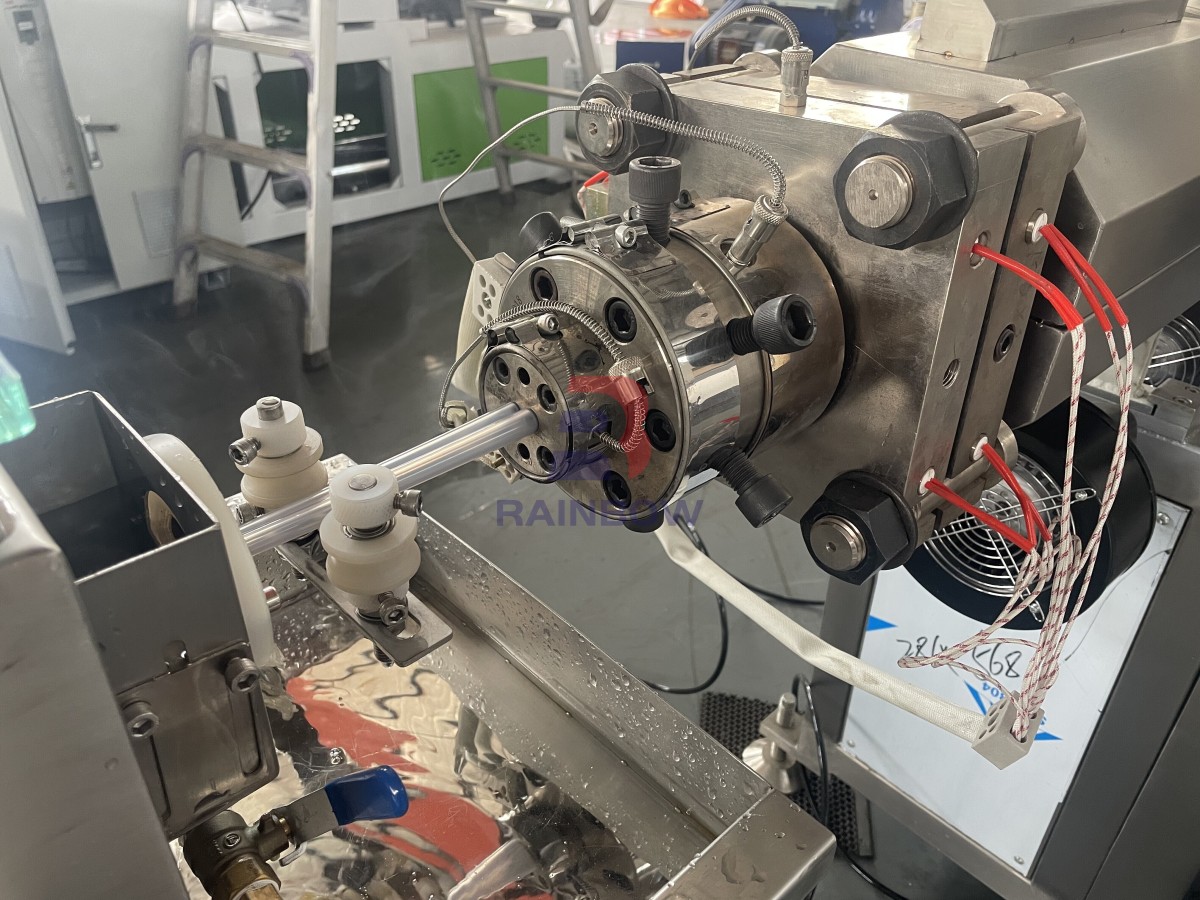

2.Mold Material: S-136H Mirror Polished Steel for Extrusion Molds

S-136H is a type of high-quality stainless steel known for its excellent polishability and corrosion resistance, making it suitable for precision extrusion molds used in medical and other high-standard applications.

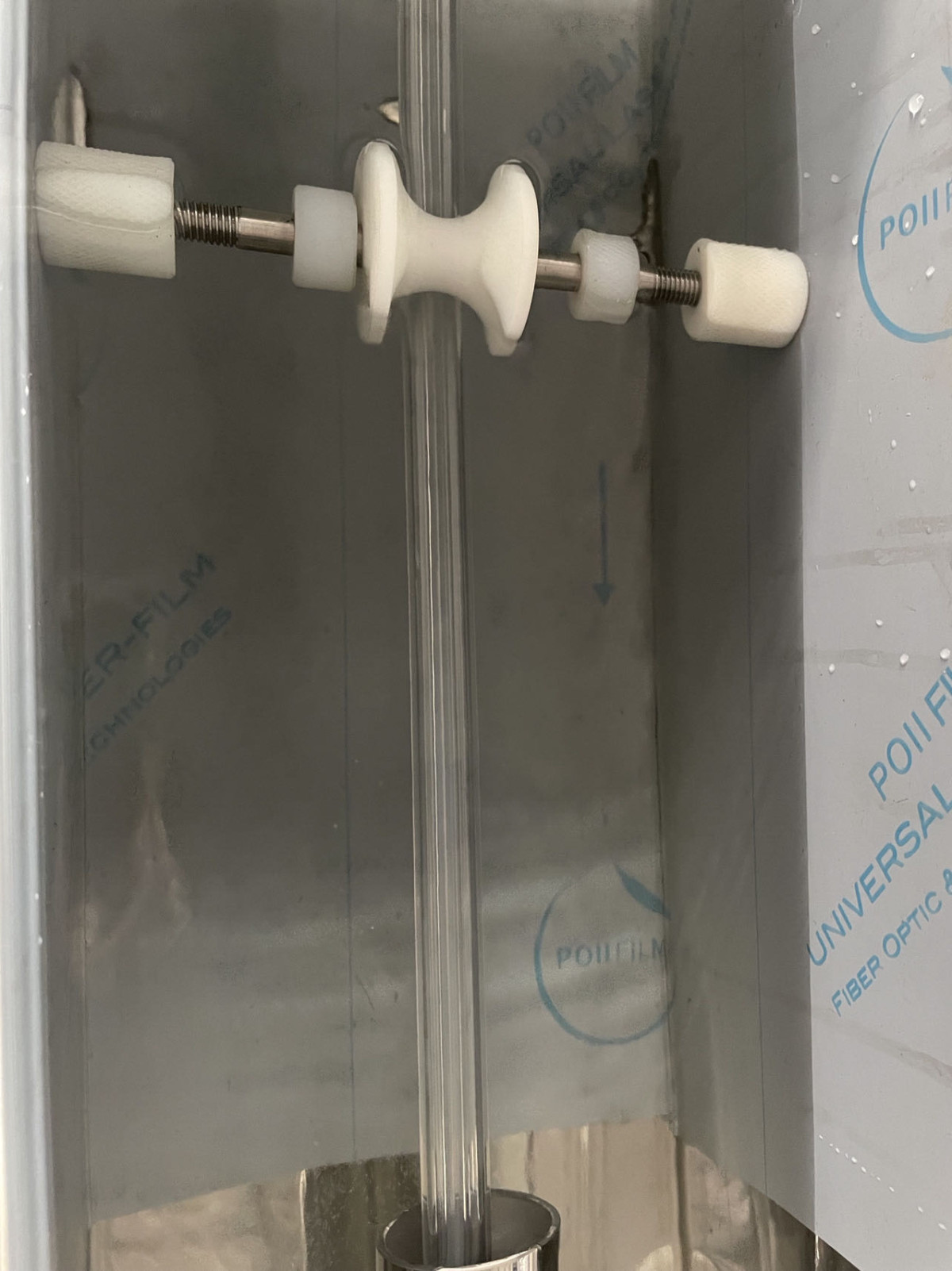

3.Medical-grade Cooling Water Tank

This component is designed to meet the stringent hygiene and safety standards required for medical applications, ensuring effective cooling of extruded materials in a controlled and sterile environment.

4.Medical-grade Precision Traction Cutting Machine

This equipment is designed to meet the high standards required for medical applications, ensuring precise cutting and handling of medical-grade materials with accuracy and reliability.

5.Dual-station Automatic Winding Machine

This equipment is designed to automatically wind materials at two stations, improving efficiency and productivity in various manufacturing processes.

Request A Quote