TPR TPE Granule Production Line

We specialize in manufacturing TPE and TPR pelletizing machines and offer customized designs to meet specific customer requirements.

Based on customer feedback and market demands, we continuously refine our designs and enhance product quality.

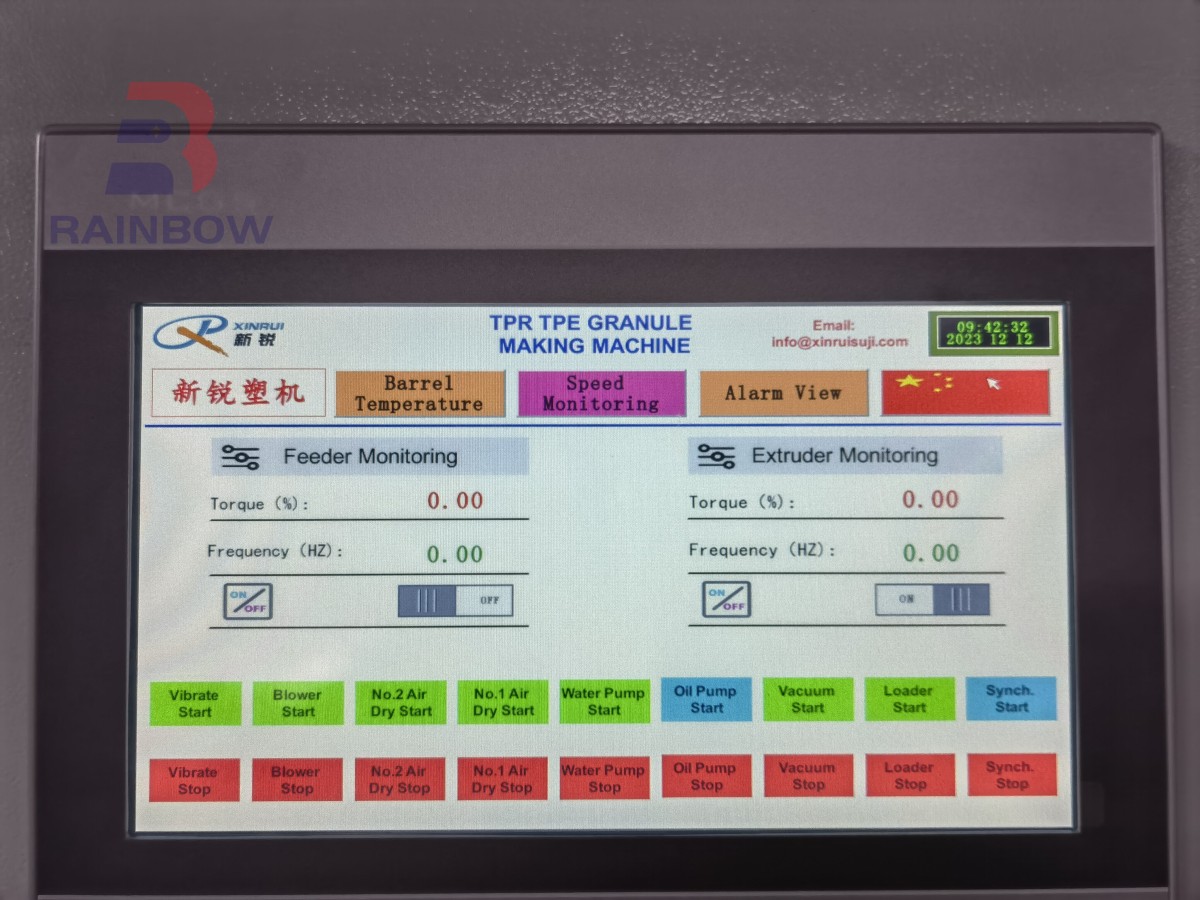

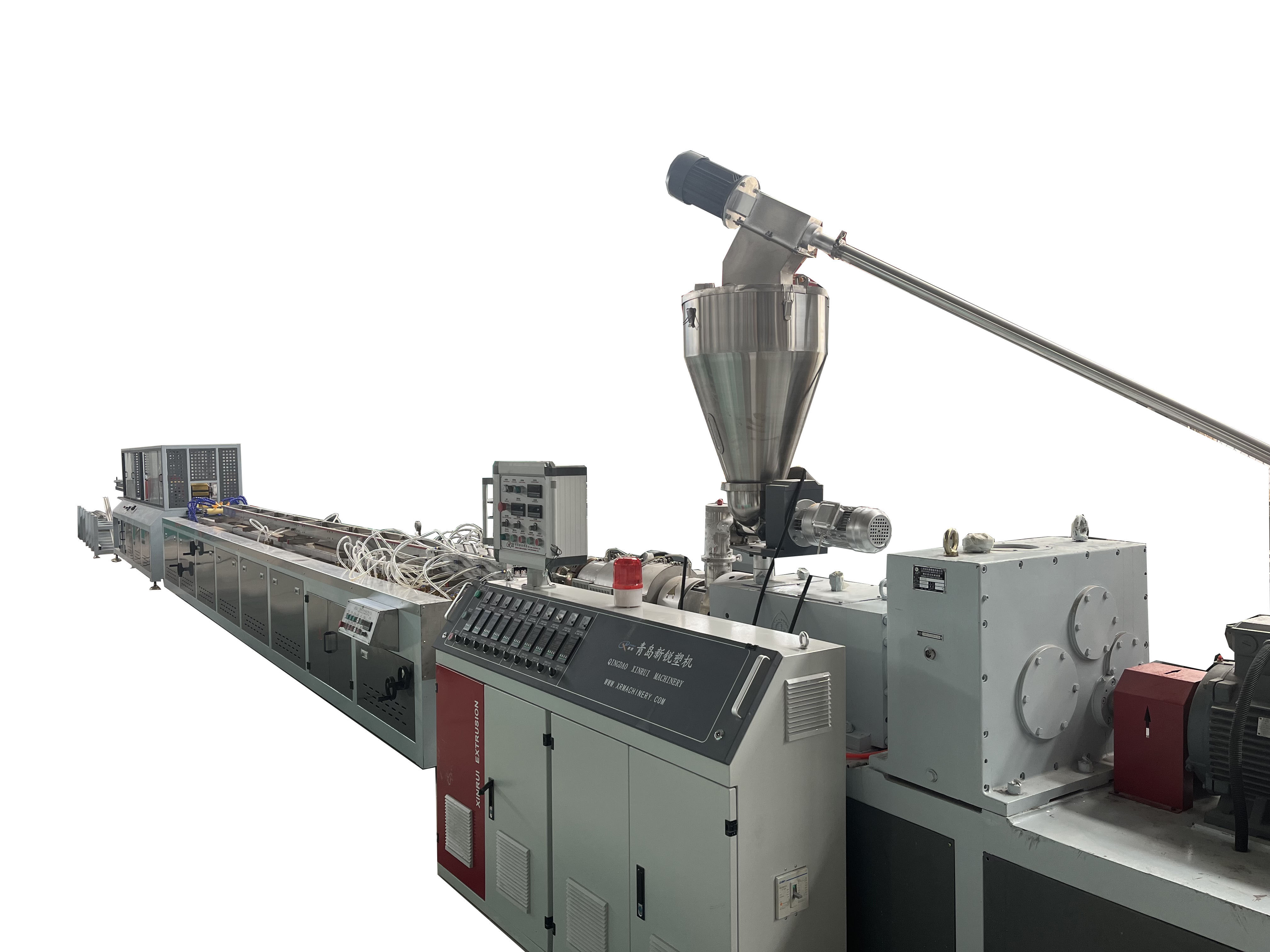

Our machines are equipped with top - tier components such as Siemens motors, ABB inverters, and Schneider Electric systems to ensure superior quality. The TPR and TPE pellet production lines feature air - cooling systems, which prevent contact between the pellets and water, thereby improving pellet quality. The extruders utilize parallel twin - screw technology, significantly boosting production capacity.

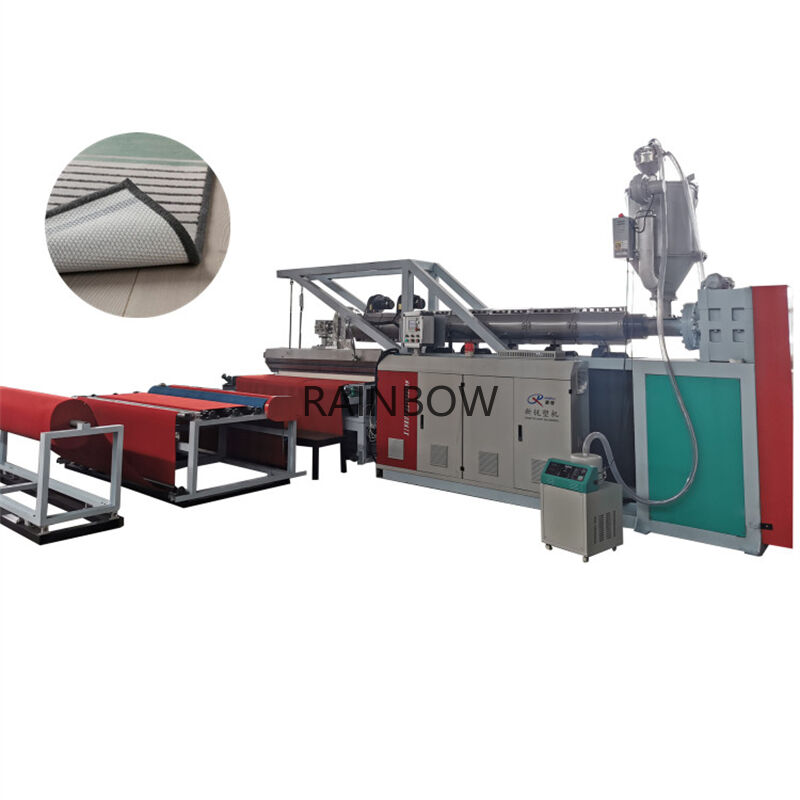

The TPR and TPE pellet production lines feature air - cooling systems, which prevent contact between the pellets and water, thereby improving pellet quality. The extruders utilize parallel twin - screw technology, significantly boosting production capacity.

The specially designed perforated screen provides precise filtration, while the frictional filter rod crushes and filters out solid impurities. These features make our system suitable for a wide range of industries, including pharmaceuticals, chemicals, and food processing.

TPR (Thermo-Plastic-Rubber) is a thermoplastic elastomer made primarily from SBS or SEBS, blended with resins (such as PP or PS), fillers, plasticizers, and functional additives. It offers excellent processing and performance advantages. Our TPR pelletizing machine ensures fast pelletizing with excellent dispersion.

Request A Quote